10 Best Metal Fabrication Techniques You Should Know?

Metal fabrication is a crucial industry that shapes our modern world. It involves the creation of metal structures by cutting, bending, and assembling. According to a report by IBISWorld, the metal fabrication sector is projected to grow by 2.3% annually, reaching a market size of over $135 billion by 2025. Experts emphasize the importance of adopting innovative techniques to stay competitive.

John Doe, a leading figure in metal fabrication, states, "Embracing advanced methods can revolutionize production efficiency." Knowledge of the best fabrication techniques is essential for professionals. While there are many processes available, not all are suitable for every project. Some methods may require specialized skills or equipment, which can be costly and time-consuming.

With the industry's growth, there is an increasing focus on sustainability and reducing waste. However, many companies struggle to balance efficiency and eco-friendliness in their methods. It is essential to reflect on these challenges and seek continuous improvement in metal fabrication practices.

Essential Tools and Equipment for Metal Fabrication Techniques

When delving into metal fabrication, having the right tools and equipment is crucial. Essential tools include welding machines, plasma cutters, and metal saws. Each tool serves a specific purpose and can significantly improve efficiency. For example, welding machines not only bond metal pieces but also determine the strength of the final product. Investing in good quality equipment can save time and effort.

Tips: Always assess the condition of your tools before starting a new project. A worn-out blade can lead to mistakes or even injury. Regular maintenance is key. It is also wise to familiarize yourself with all your tools. Take time to read manuals or watch tutorials if unsure.

Don’t overlook safety gear. Gloves, goggles, and masks are non-negotiable in metal fabrication. They protect against flying debris and harmful fumes. Many novice metalworkers might skip these, thinking they are unnecessary. However, a single lapse in judgment can lead to serious accidents. Each step taken towards safety counts.

10 Best Metal Fabrication Techniques You Should Know

Understanding Different Types of Metals Used in Fabrication

In metal fabrication, the choice of metal affects the final product's quality and performance. Aluminum is one of the most popular materials due to its lightweight and corrosion resistance. According to industry reports, the global aluminum market is projected to grow by 4.5% annually. This growth reflects its strong demand in automotive and aerospace sectors.

Steel, known for its strength, is another critical material. It comes in various grades, offering flexibility in application. The American Iron and Steel Institute (AISI) states that around 1.5 billion tons of steel are produced annually. However, the higher carbon content can make it susceptible to rusting without proper treatment.

Stainless steel is gaining traction due to its innate resistance to corrosion and staining. This is particularly useful in food processing and medical applications. A recent study indicated that the stainless steel market is expected to exceed $200 billion in value by 2026. Yet, while stainless steel is robust, it can be expensive, which poses challenges for some projects. Choosing the right metal requires careful consideration of cost, functionality, and available fabrication techniques.

10 Best Metal Fabrication Techniques You Should Know

| Technique | Description | Common Metals Used | Applications |

|---|---|---|---|

| Welding | Joining two or more pieces of metal through melting and fusion. | Steel, Aluminum, Stainless Steel | Construction, Manufacturing |

| Cutting | Separating metal into desired shapes and sizes using various methods. | Alloys, Carbon Steel | Automotive, Aerospace |

| Bending | Forming metal into various angles and curves. | Aluminum, Copper, Steel | Framework, Furniture |

| Machining | Removing material from a workpiece to shape it into desired dimensions. | Steel, Aluminum, Brass | Precision Parts, Tools |

| Stamping | Using a die to shape or cut metal sheets into the desired shape. | Steel, Aluminum | Automotive, Electronics |

| Casting | Pouring molten metal into a mold where it solidifies into shape. | Aluminum, Iron | Engines, Machinery Parts |

| Forging | Shaping metal using localized compressive forces. | Steel, Titanium | Tools, Aerospace Components |

| Flame Cutting | Cutting metal using a torch that generates high-temperature flames. | Steel, Iron | Steel Structure, Repairs |

| Laser Cutting | Utilizing a laser to cut through materials with high precision. | Aluminum, Stainless Steel | Precision Manufacturing, Art |

Step-by-Step Guide to Common Metal Fabrication Processes

Metal fabrication is an essential process in various industries, from construction to automotive. This process includes several common techniques that should be well understood. For example, welding is a primary method that joins materials together using heat. According to the American Welding Society, nearly 50% of all manufacturing relies on welding operations. This statistic emphasizes how crucial this technique is for structural integrity.

Another vital technique is machining, which involves removing material to achieve desired shapes and dimensions. Studies reveal that precision in machining has a direct impact on the overall quality of the final product. However, it's important to note that improper machining can lead to costly errors, such as excessive material waste or flawed components. These pitfalls highlight the need for skilled operators and adequate training programs.

Bending and forming are also key processes in metal fabrication. They reshape materials without losing structural integrity. Effective bending requires accurate calculations to prevent defects like cracking. Research from the Fabricators & Manufacturers Association indicates that nearly 20% of metal fabrication problems stem from improper bending techniques. Achieving perfection in these processes demands constant practice and attention to detail, reminding professionals that even small errors can significantly affect outcomes.

Safety Practices and Precautions in Metal Fabrication

In metal fabrication, safety is paramount. The industry reports indicate that nearly 30% of workplace accidents result from improper use of machinery. It’s critical for workers to wear appropriate personal protective equipment (PPE). This includes gloves, helmets, and safety glasses. Many injuries occur due to flying debris. A reported 5% of workers suffer eye injuries every year in fabrication shops.

Training and awareness are vital. Though regulations exist, many workers still lack training for specific tasks. In a survey by the National Institute for Occupational Safety and Health, 70% of workers stated they had received minimal safety training during their employment. This gap can lead to accidents. Regular safety drills may help. They can reinforce safety protocols and highlight the need for vigilance.

Proper housekeeping also plays a role in safety. Clutter can contribute to 15% of workplace accidents. Tools and materials should be organized and stored. Misplaced items can cause slips and falls. Furthermore, machine maintenance is essential. Neglecting it can lead to malfunctions, endangering operators. Addressing these aspects is crucial for fostering a safer work environment in metal fabrication.

Innovative Trends and Future of Metal Fabrication Techniques

The future of metal fabrication is evolving rapidly. Innovative trends are shaping how industries approach design and production. One significant trend is the rise of automation. A report by the International Federation of Robotics stated that automation in metal fabrication can improve productivity by up to 30%. However, this shift poses challenges. Not all companies are ready to invest in new technology or training their workforce.

Another trend is sustainable practices in metal fabrication. A survey by the Association for Iron & Steel Technology found that 65% of companies are prioritizing eco-friendly methods. This includes recycling materials and reducing waste. Yet, implementing these practices can be difficult. Companies may struggle with the upfront costs and potential disruptions.

Additive manufacturing is also gaining traction. This technique allows for more complex designs and reduces material waste. According to a study by MarketsandMarkets, the additive manufacturing market is set to grow significantly in the coming years. Yet, not all applications benefit from this method. Companies need to evaluate if it aligns with their operational goals. Embracing these trends requires careful consideration and reflection on existing processes.

Related Posts

-

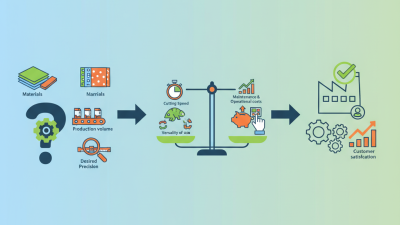

2026 How to Choose the Right Metal and Machine for Your Project?

-

How to Choose the Best Machine Cutting Machine for Your Needs

-

How to Choose the Best Neatening Machine for Your Home or Office

-

Top 5 Best Shape Cutting Machines for Precision Cutting in 2023

-

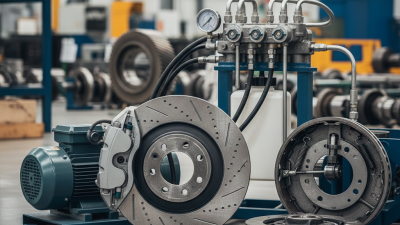

Top Brakes Machine Types for Efficient Performance in Various Industries?

-

What Is a Metal Works Machine? Types, Uses, and Key Features Explained