Top 5 Best Shape Cutting Machines for Precision Cutting in 2023

In the world of precision manufacturing, shape cutting machines stand as a pivotal tool. Numerous industries rely on them for accuracy and efficiency. As noted by industry expert Dr. Emily Hart, "A quality shape cutting machine can transform cutting processes, but precision is key." Her insight sheds light on the importance of choosing the right equipment.

With the rising demand for high-quality cuts, the market offers various options. Some machines excel in speed while others prioritize detail. This diversity can lead to confusion for buyers seeking the best fit. Each machine brings unique features. Users should reflect on their specific needs and the nuances of different models.

While advancements have been remarkable, not every machine meets expectations. Some users report inconsistencies. Thorough research is essential. Understanding the intricacies of shape cutting machines can help avoid pitfalls. As we explore the top five machines for 2023, the focus will remain on features, reliability, and user experience.

Overview of Shape Cutting Machines and Their Importance

Shape cutting machines play a crucial role in various industries. Their accuracy is vital for producing detailed products, from intricate designs to basic patterns. These machines streamline processes and enhance creativity. Without precise cutting, even simple projects can become frustrating and time-consuming.

Choosing the right shape cutting machine requires care. Consider your specific needs and the materials you’ll work with. Test different machines before making a final decision. Make a list of features that matter to you. Performance, ease of use, and price should reflect your goals.

Tip: Always maintain your machine. Regular cleaning and service prolong its life. Check blades often; dull blades can ruin projects.

Accuracy can vary by machine. Ensure you do test cuts before starting significant work. This practice helps to avoid wasted materials. Remember, mistakes happen even to professionals. Reflect on what went wrong to improve your skills. Embrace the learning curve; it’s part of the journey.

Key Features to Consider When Choosing a Precision Cutting Machine

When selecting a precision cutting machine, key features play a crucial role. First, consider the cutting material. Different machines excel with various materials. For example, some are better suited for paper, while others handle wood or fabric well. Understand your needs and select accordingly.

Next, evaluate the machine's cutting speed. A faster machine can increase productivity, but it may sacrifice precision. Finding a balance is important. Look into the blade options, too. Sharp, high-quality blades ensure cleaner cuts. Dull blades lead to frustration and uneven edges. Users often overlook maintenance, which is essential for consistent performance.

Finally, check the size and portability of the machine. Some users need a compact design for small workspaces. However, larger machines may offer more features and capabilities. Weighing space against functionality is a common dilemma. Remember, the best choice often requires some trial and error. What works for one project may not suit another.

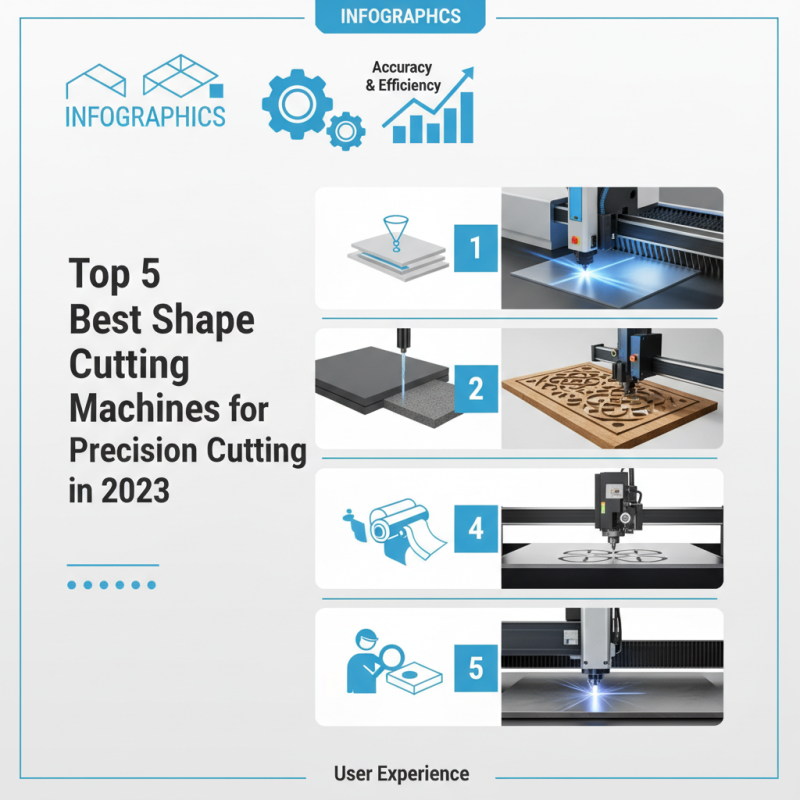

Top 5 Best Shape Cutting Machines for Precision Cutting in 2023

This bar chart displays the precision scores of the top five shape cutting machines for 2023. A higher score indicates better performance in precision cutting, helping users choose the right machine based on their needs.

Top 5 Shape Cutting Machines for Precision in 2023

In 2023, precision shape cutting machines are essential tools in various industries. They enable users to create intricate designs with high accuracy. This precision is crucial for projects in crafts, manufacturing, and construction. Many users struggle to find machines that balance quality and ease of use. The right machine can significantly enhance productivity while minimizing waste.

Some models stand out for their user-friendly interfaces. Operators can configure settings without extensive training. However, there are always challenges. Occasionally, machines may misinterpret designs or fail to cut through thicker materials. This can lead to frustration and delays. Regular maintenance can mitigate these issues, but it requires commitment. Investing time in learning machine intricacies pays off in the long run.

Moreover, affordability is a key consideration. Many consumers seek budget-friendly options without sacrificing quality. It’s a complicated balance. A cheaper machine might lack crucial features, impacting overall performance. Finding a reliable source for recommendations is vital. Users should weigh reviews carefully and consider their own needs. This approach can lead to better decisions and more successful outcomes.

Comparative Analysis of the Best Cutting Machines

When selecting the best shape-cutting machines for precision work, there are several critical factors to consider. The machines vary widely in capabilities. They offer different cutting widths, depths, and materials compatibility. Ensure you understand your project needs before you buy. Some machines excel at intricate designs, while others focus on speed. This difference can be pivotal for timely project completion.

Many users report challenges with setup. Sometimes, the calibration of these machines is not intuitive, and this can lead to frustration. Precision cutting demands accurate measurements. A minor miscalculation can result in wasted materials. Check user reviews for common issues. Some cutting machines, while efficient, may struggle with thicker materials or complex patterns.

Price points can be misleading. A higher price does not always guarantee better performance. Understanding what features are essential for your tasks is vital. Some machines come with advanced software for design. This can increase usability but may also lead to a steeper learning curve. Reflect on whether those features align with your skills and needs. Opting for a machine that suits your style can provide you with better satisfaction and results.

Top 5 Best Shape Cutting Machines for Precision Cutting in 2023

| Model | Cutting Area (inches) | Precision (mm) | Speed (inches/sec) | Weight (lbs) | Price ($) |

|---|---|---|---|---|---|

| Model A | 12 x 12 | 0.1 | 25 | 15 | 299 |

| Model B | 10 x 10 | 0.08 | 30 | 12 | 249 |

| Model C | 14 x 14 | 0.15 | 20 | 18 | 349 |

| Model D | 16 x 16 | 0.1 | 27 | 20 | 399 |

| Model E | 18 x 18 | 0.12 | 22 | 24 | 499 |

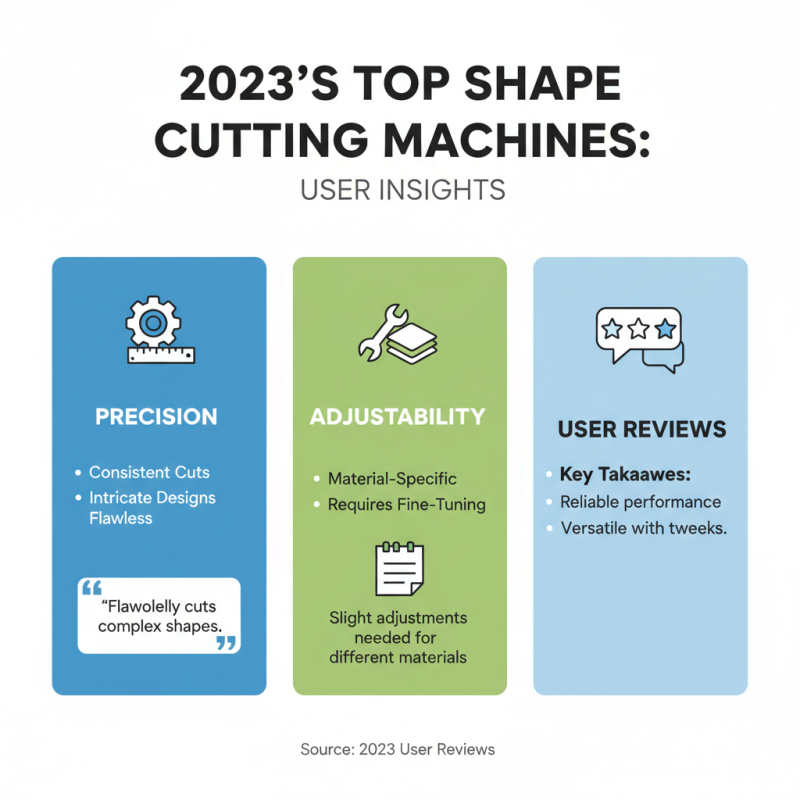

User Reviews and Experiences with Each Recommended Machine

When exploring the best shape cutting machines of 2023, user reviews reveal helpful insights. Many users appreciate machines that offer consistent precision. One user remarked on a machine’s ability to cut intricate designs flawlessly. However, slight adjustments were necessary for different materials.

Some users faced challenges. One user noted occasional calibration issues that affected accuracy. Another mentioned that the learning curve was steeper than expected. Yet, the resulting cuts made the effort worthwhile. Feedback consistently highlighted the importance of patience and practice with each device.

Users also appreciated accessible support resources. Many found online tutorials invaluable for mastering techniques. Several shared their excitement about creating projects like custom stencils and decorations. While perfection isn’t guaranteed, the overall experiences show that with time and effort, these machines can yield impressive results.