2026 How to Choose the Right Fabrication Cutting Machine for Your Needs?

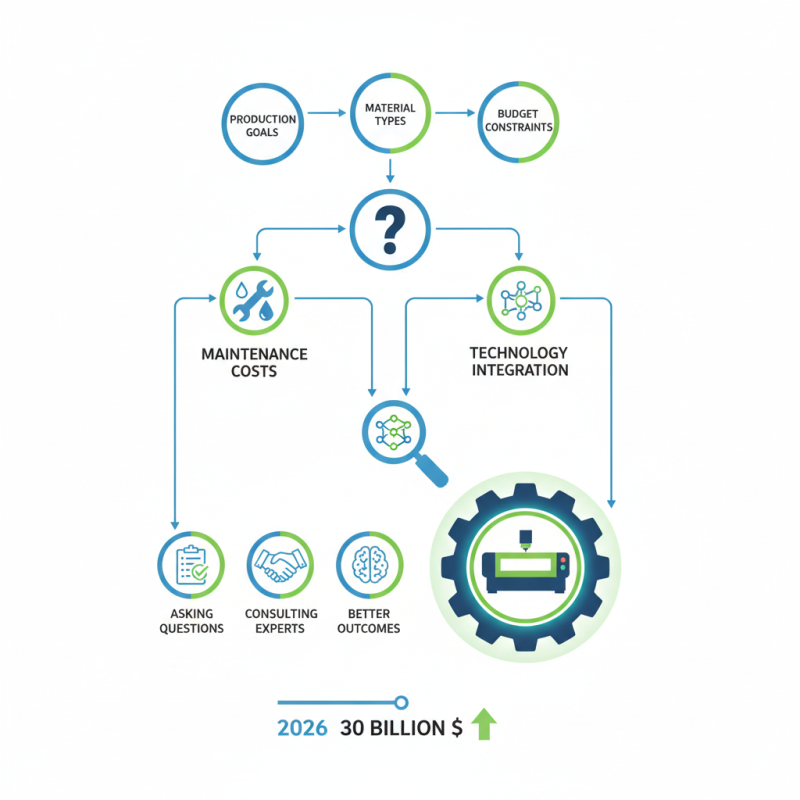

Choosing the right fabrication cutting machine is vital for any manufacturing operation. The global fabrication machinery market is projected to reach $30 billion by 2026, according to industry reports. Companies face many options, each with unique features and capabilities.

Expert Dr. Emily Carter, a leading figure in fabrication technology, states, "The choice of a cutting machine can define the efficiency of an entire production line." Her insight underscores the importance of assessing one’s specific needs. The right machine must align with production goals, material types, and budget constraints.

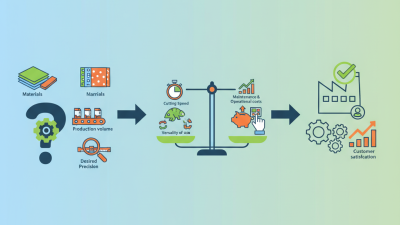

Yet, many businesses struggle with this decision. They often overlook key factors, like maintenance costs or technology integration. These oversights can lead to inefficiencies and lost profits. A machine that seems ideal may not be suitable in real-world applications. Asking the right questions and consulting industry experts can yield better outcomes.

Factors to Consider When Selecting a Fabrication Cutting Machine

When selecting a fabrication cutting machine, various factors play a crucial role. One significant aspect is the type of materials you plan to cut. Different machines excel with specific materials. For instance, laser cutting machines are ideal for metals, while water jet cutters work well with composites and ceramics. According to a report by Global Market Insights, the laser cutting machine market is projected to reach $2.6 billion by 2026. This growth showcases the rising demand for precise cutting technologies.

Another vital consideration is the thickness of the materials. Machines have varying capabilities. For example, some can handle materials up to 1 inch thick, while others may struggle with anything over 0.25 inches. A study showed that 70% of users experienced inefficiencies due to mismatched machine specifications. This highlights the need for proper alignment between machine capabilities and project requirements.

Cost is also a critical factor. While investing in high-end machinery may seem beneficial, operational costs must be factored in. Maintenance, energy usage, and consumables add up. A budget that only focuses on initial costs could lead to disappointments in the long run. Balancing cost and performance ensures sustainability in your operations.

Types of Fabrication Cutting Machines Available on the Market

When selecting a fabrication cutting machine, understanding the types available is crucial. There are several modes in the market today, including laser cutting, plasma cutting, and water jet cutting. Each serves different applications, and their features vary significantly.

Laser cutting machines are known for their precision. They can cut various materials, including metals, plastics, and wood. According to a research report by MarketsandMarkets, the global laser cutting machine market is expected to reach $5.5 billion by 2026, growing at a CAGR of 6.1%. However, they may not be the best choice for thicker materials, as their cutting depth can be limited.

Plasma cutting is favored for its speed and versatility. It works well with thick metals, making it popular in industries like manufacturing and construction. A key point to consider is its finishing quality, which can sometimes leave rough edges. Water jet cutting stands out for its ability to cut virtually any material without heat. Yet, its slower speed may not suit time-sensitive projects.

Choosing the right machine involves assessing these strengths and weaknesses. A common issue is balancing quality, speed, and material compatibility. Understanding this trade-off is vital in selecting a suitable fabrication cutting machine.

Types of Fabrication Cutting Machines Available on the Market

Assessing Your Material Compatibility and Thickness Requirements

Choosing the right fabrication cutting machine requires a deep understanding of material compatibility and thickness requirements. Different machines excel with various materials. For instance, laser cutters work best with thin materials like acrylic and aluminum. According to a recent industry report, over 40% of manufacturers encounter issues due to mismatched material thickness.

When assessing thickness requirements, consider that cutting machines have limits. Waterjet cutters can handle thicker materials, often exceeding 10 inches for some types. However, they may struggle with precision on thinner materials. In contrast, plasma cutters offer speed for thicker metals but can cause warping on thinner sheets. This compromise can lead to production delays, negatively affecting efficiency.

It’s vital to match your machine with the materials you frequently use. A common oversight is assuming one machine can handle all tasks. A recent survey revealed that 30% of operators regretted their machine choice due to material incompatibility. This highlights the importance of thorough research and realistic assessments of your specific needs before making a significant investment.

Evaluating Machine Features and Specifications for Performance

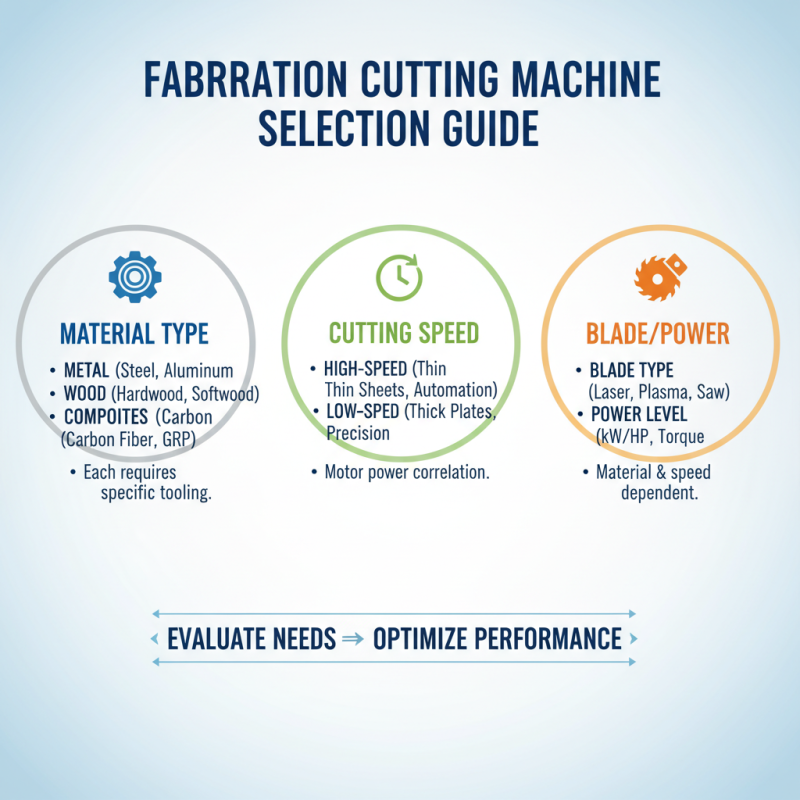

Choosing the right fabrication cutting machine requires careful evaluation of key features and specifications. Focus on the type of materials you will be cutting. Different machines excel at cutting metal, wood, or composite materials. Each material requires specific cutting speeds, blade types, and power levels. For instance, high-speed applications may need a more powerful motor.

Accuracy is another essential factor. Machines with advanced laser or plasma cutting technology often provide better precision. This aspect is crucial for intricate designs. However, machines with higher accuracy might come with higher costs. Assess your budget to find a balance between performance and affordability.

Consider user-friendliness as well. A complicated interface can slow down production. Simplicity matters, especially for training new operators. Even machines with excellent specs can become underutilized if they are not easy to operate. Thus, ensure the machine meets your team's skill level. Evaluate these elements thoroughly to avoid future regrets. A mismatch of features can lead to inefficiency. Always take time to reflect on what each specification means for your specific needs.

Budget Considerations and Cost-Effectiveness of Cutting Machines

When choosing a fabrication cutting machine, budget is crucial. Assessing the price range can help narrow options. Look for machines that fit your financial plan. However, many overlook hidden costs. Maintenance, tooling, and operation expenses add up quickly. It's essential to factor these into your overall budget.

Cost-effectiveness often hinges on the machine's efficiency. A cheaper machine might save money upfront but could lead to higher operational costs. Consider long-term gains versus short-term savings. A well-designed machine usually operates faster and consumes less energy. Inconsistent performance might deter productivity.

Don’t forget about scalability. A machine suitable for current needs may not meet future demands. Future-proofing investments can help avoid frustrations. Rethink your choices if the machine limits potential growth. Balancing initial costs with future needs can be challenging but necessary. Explore all factors for a wise decision.

Related Posts

-

Top 5 Best Shape Cutting Machines for Precision Cutting in 2023

-

How to Choose the Best Arc Cutting Machine for Your Needs?

-

What Is a Metal Works Machine? Types, Uses, and Key Features Explained

-

Top Brakes Machine Types for Efficient Performance in Various Industries?

-

How to Choose the Best Machine Cutting Machine for Your Needs

-

2026 How to Choose the Right Metal and Machine for Your Project?