How to Choose the Best Arc Cutting Machine for Your Needs?

Choosing the right arc cutting machine is crucial for efficiency and precision in metalworking. According to industry expert John Smith, "The right arc cutting machine can transform your workflow." His insight reflects the importance of selecting equipment that fits specific needs.

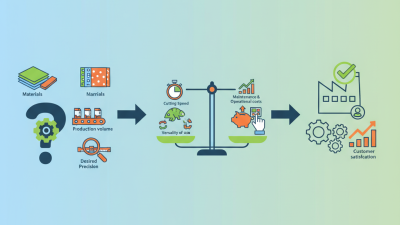

When considering an arc cutting machine, think about your project's demands. Different machines offer various features, including power levels and cutting capabilities. Evaluate how often you'll use the machine and what materials you'll work with. It's a balance of quality and budget.

Not every arc cutting machine is perfect for every application. Some may lack necessary features or reliability. Always be ready to reassess your choices and gather feedback from other users. This reflection can lead to finding the machine that truly enhances your work process.

Understanding Different Types of Arc Cutting Machines and Their Applications

When selecting an arc cutting machine, understanding its types is crucial. Plasma arc cutters are popular for their speed and precision. They work well on thin metals and produce clean cuts. However, they may struggle with thicker materials. On the other hand, gas arc cutting machines excel in cutting thick steel. They are more versatile for heavy-duty tasks but require more setup time.

Electric arc cutting machines provide a distinct option. They use a high-heat arc to melt metals, fitting for repair jobs and industrial applications. Their efficiency reduces manual labor but can produce a rougher cut. Users sometimes find the operation complex. Training is essential to minimize errors and enhance safety.

Choosing the right machine goes beyond just understanding types. Consider your specific needs and the materials you work with. Each machine has strengths and weaknesses. Evaluate your workload and frequency of use. Optimal choices reflect both capacity and skill level. An informed decision leads to better results in cutting tasks.

Comparison of Different Types of Arc Cutting Machines

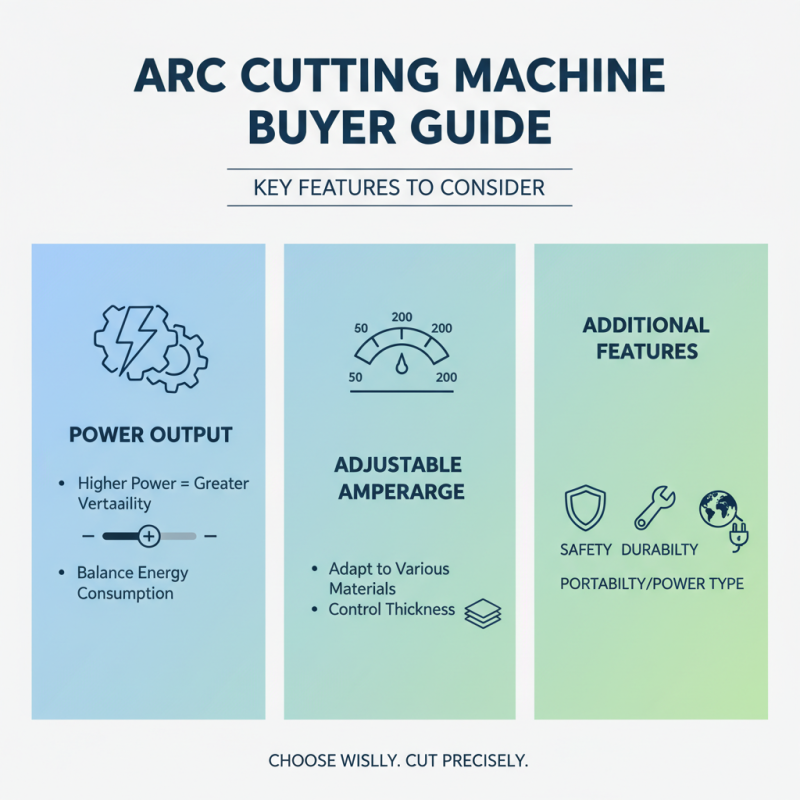

Key Features to Consider When Selecting an Arc Cutting Machine

When choosing an arc cutting machine, several key features can make a significant difference. First, consider the power output. A higher power rating often means more versatility. But, this can also lead to increased energy consumption. Balance is crucial here. Look for machines that provide adjustable amperage settings. This way, you can easily adapt to various materials and thicknesses.

Another feature to pay attention to is the machine's portability. If you need to move it between job sites, weight and design matter. Some machines are compact and lightweight, making them easier to transport. However, lightweight models may compromise on durability. It's essential to evaluate what you'll prioritize.

Finally, think about the user interface. A clear and intuitive control panel can save time and reduce errors. Sometimes, too many features can overwhelm a user. It’s important to ensure that the essential functions are straightforward. Paying attention to these details can enhance your overall cutting experience. But, remember, the best choice will depend on your specific needs and circumstances.

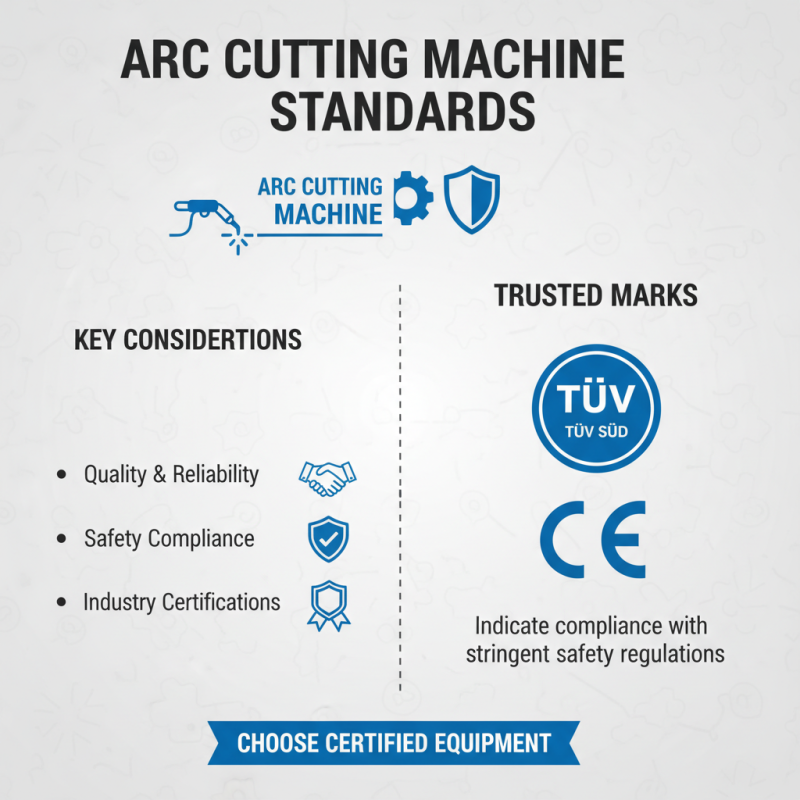

Analyzing Industry Standards and Performance Metrics in Arc Cutting

When selecting an arc cutting machine, understanding industry standards is crucial. These standards help define the equipment's quality, reliability, and safety. Look for machines that meet certification requirements. Pay attention to the TÜV and CE marks, as they indicate compliance with stringent safety rules.

Performance metrics also play a significant role. Assess cutting speed and maximum thickness. Some machines cut faster than others. Ensure the machine can handle your materials effectively. Consider versatility; machines that can cut various metals may be more beneficial.

Tips: Always read reviews from other users. They can provide insights into the machine's real-world performance. Also, consider the machine's maintenance needs. Machines with simpler maintenance protocols may be more reliable over time. Lastly, don’t ignore energy consumption. Machines that use less power can save on costs in the long run.

Remember, not all machines are perfect for every task. Sometimes, a machine might excel in cutting thickness but lack precision. Reflect on your specific needs before making a choice.

Evaluating Cost-Effectiveness and Return on Investment for Arc Cutting Tools

When evaluating arc cutting machines, cost-effectiveness is crucial. The initial investment can be significant. You should consider not just the price tag but also the long-term savings. Look at energy efficiency and maintenance costs. An efficient machine can cut down on energy use. Regular maintenance impacts overall expenses.

Consider how often you will use the machine. A heavy-duty model might seem appealing, but it’s wise to reflect on your actual needs. If you cut materials infrequently, a more basic machine could work. Additionally, think about the time spent on each job. Fast machines often justify their higher costs through increased productivity. Factor this into your calculations.

ROI is not just about what you spend. It's also about how much profit you generate. Sometimes, a cheap option can lead to frustrating results. Parts may wear out quickly. Downtime can eat into your budget. Assess all these factors carefully. It is vital to choose wisely for the best overall value in the long run.

Safety Standards and Best Practices for Using Arc Cutting Machines

When using arc cutting machines, safety must come first. Protective gear is essential. This includes gloves, goggles, and flame-resistant clothing. Failure to wear safety equipment can lead to serious injuries. Sparks and heat are common hazards. Even a moment of carelessness can result in painful burns.

It's crucial to maintain a clean workspace. Clutter can lead to accidents. Ensure no flammable materials are nearby. Proper ventilation is also important. Fumes from cutting can be harmful. Assess your environment before starting any work. Having a fire extinguisher on hand is a best practice.

Even experienced operators must reflect on their techniques. Constantly check equipment for wear and tear. Old cables and equipment can malfunction. Test the machine before starting a project. Small lapses can have large consequences. Always stay vigilant and ready to adapt.

Related Posts

-

Top 5 Best Shape Cutting Machines for Precision Cutting in 2023

-

Top Brakes Machine Types for Efficient Performance in Various Industries?

-

How to Choose the Best Machine Cutting Machine for Your Needs

-

What Is a Metal Works Machine? Types, Uses, and Key Features Explained

-

2026 How to Choose the Right Metal and Machine for Your Project?

-

How to Choose the Best Neatening Machine for Your Home or Office