How to Choose the Best Machine Cutting Machine for Your Needs

Choosing the right machine cutting machine is essential for any operation that relies on precision and efficiency in their cutting processes. Whether you are involved in manufacturing, crafting, or any other industry that requires cutting materials, the type of machine cutting machine you select can significantly impact your workflow and final product quality. Understanding your specific needs, including the materials you will be cutting, the volume of production, and the desired precision, is fundamental to making an informed decision.

When evaluating various machine cutting machines, consider factors such as cutting speed, versatility, and ease of use. You should also take into account the maintenance and operational costs associated with each machine, as these can vary widely depending on technology and design. Furthermore, assessing the scalability of the machine in relation to your business growth can help you invest wisely and avoid future limitations. Ultimately, the right machine cutting machine will not only enhance your productivity but also ensure that you meet the demands of your customers with accuracy and reliability.

Understanding the Different Types of Machine Cutting Machines

When selecting a machine cutting machine, it's essential to understand the various types available and how they suit different projects. The primary types include laser cutting machines, plasma cutting machines, waterjet cutting machines, and mechanical cutting machines. Each type has its unique strengths: laser cutters are known for their precision and ability to cut intricate designs, while plasma cutters are favored for their speed and efficiency in thicker materials. Waterjet machines, on the other hand, excel in cutting delicate materials without heat distortion, and mechanical cutters are reliable for standard cutting tasks across various materials.

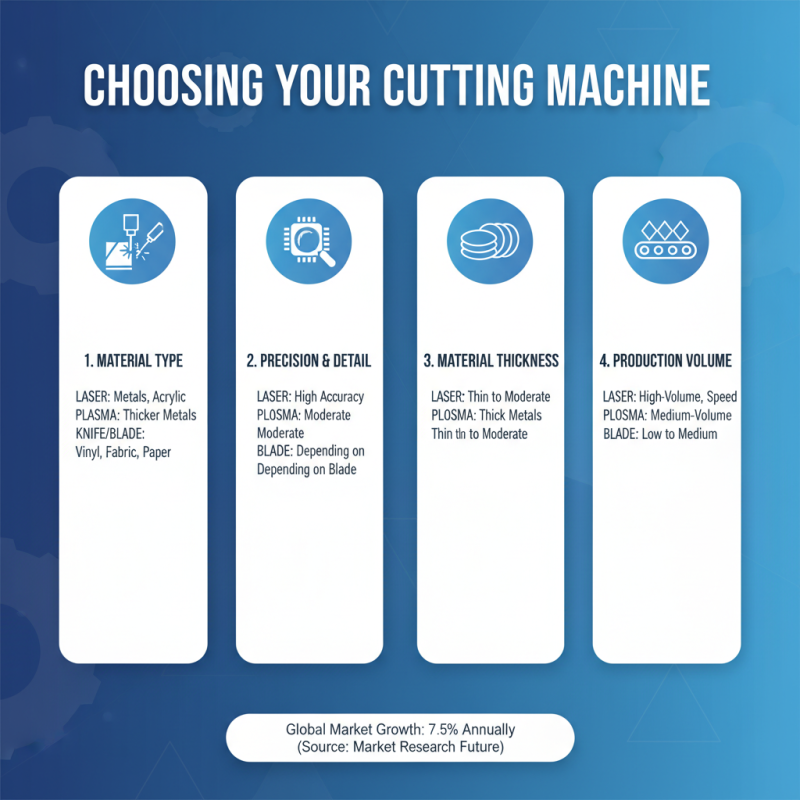

Tips: When choosing a machine, consider the specific materials you will be working with. For instance, if you're primarily cutting metal, a plasma or laser cutting machine may be more suitable. Also, assess the thickness of the materials; if you're dealing with thicker components, ensure the machine can handle the required capacity.

Another factor to consider is the intended volume of production. If your projects are high-volume and require speed, a plasma cutter could be a better fit. However, if precision and intricate detail are paramount, investing in a laser cutting machine will pay off. Remember to also factor in maintenance and operating costs, as these can vary significantly across different cutting technologies.

Key Factors to Consider When Choosing a Cutting Machine

When choosing the best cutting machine for your needs, several key factors must be considered to ensure the equipment meets your specific requirements. One of the most important aspects is the material type you will be working with. According to a report by Market Research Future, the demand for cutting machines is projected to grow by 7.5% annually, primarily driven by the increasing use of advanced materials across various industries. For instance, laser cutting machines are greatly favored for their precision when dealing with metals, while plasma cutting is more effective for thicker materials.

Another critical factor to consider is the machine's cutting capabilities, including speed and power. A study from the International Journal of Advanced Manufacturing Technology highlights that machines with higher power ratings can significantly increase productivity rates. It's essential to evaluate the machine's cutting thickness and speed specifications in conjunction with your production needs—higher speeds might be advantageous, but they can compromise quality if not monitored carefully. Additionally, understanding the available features such as software integration, ease of operation, and maintenance needs can play a crucial role in optimizing your efficiency and reducing downtime in the long run.

Assessing Your Material Compatibility with Cutting Machines

When choosing a machine cutting machine, assessing your material compatibility is crucial for achieving optimal results. Different materials, such as wood, metal, plastic, and composites, require specific cutting technologies and methods. For instance, while a laser cutting machine excels in precision for thin metals and intricate patterns, a band saw is more effective for thicker materials and curves. Understanding the nature of the material you intend to cut will guide you to the best cutting solution, ensuring efficiency and quality in your projects.

Furthermore, consider the hardness, thickness, and thermal properties of your materials. Harder materials may require more robust machinery with specialized cutting tools, while highly reflective materials might necessitate machines designed to minimize glare and distortion. It's also essential to think about the production volume; some machines are better suited for high-volume production, while others are ideal for prototyping or one-off projects. By thoroughly evaluating the material you plan to work with, you can choose a cutting machine that not only meets your operational requirements but also enhances your overall productivity.

Material Compatibility with Cutting Machines

Evaluating the Precision and Speed of Cutting Machines

When selecting a cutting machine, two critical factors to consider are precision and speed. Precision is paramount, especially in applications that require intricate detailing or accurate measurements. A machine that consistently delivers high precision reduces waste and the need for rework, ultimately saving time and resources. Features that enhance precision include advanced cutting technologies such as laser or water jet cutting systems, as well as the machine's ability to maintain a consistent margin and avoid deviations during operation.

Speed is equally important, particularly in high-volume production environments where time directly correlates with profitability. A machine capable of rapid cutting without sacrificing quality can significantly enhance overall productivity. When assessing speed, it is essential to consider both the operational speed of the machine and the setup time required between cuts. Additionally, the ability to automate processes can contribute to faster output, allowing operators to focus on other essential tasks while the machine handles repetitive cutting jobs. Balancing these two aspects—precision and speed—will help ensure that the chosen cutting machine meets your specific operational requirements efficiently.

Budgeting for Your Machine Cutting Needs and Long-Term Maintenance

When budgeting for a machine cutting machine, it is crucial to consider both the initial investment and the long-term maintenance costs. According to a report by IBISWorld, the machine manufacturing industry has seen a steady growth of approximately 3.5% annually, indicating a growing demand for efficient and reliable cutting machines. Potential buyers should allocate roughly 15-20% of their initial purchase cost for maintenance over the machine's lifespan. This includes routine servicing, replacement parts, and potential upgrades, ensuring optimal performance and longevity.

In addition to initial and maintenance costs, it's essential to factor in energy consumption. The U.S. Department of Energy estimates that machinery accounts for about 30% of a facility's total energy use. Investing in energy-efficient models can significantly reduce operating costs over time. Furthermore, integrating advanced technologies like automation or precision cutting can lead to lower waste and better material utilization—enhancing overall cost-effectiveness. By carefully assessing both upfront and ongoing expenses, businesses can make informed decisions that align with their operational needs and budgetary constraints.