2026 How to Choose the Right Metal and Machine for Your Project?

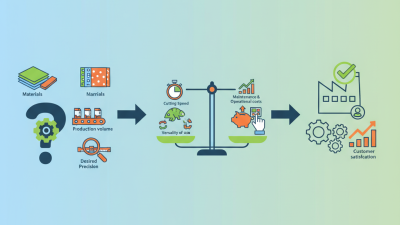

Choosing the right metal and machine for your project can significantly impact its success. The global metal manufacturing market was valued at around $1 trillion in 2022 and is expected to grow. Selecting the appropriate materials and machinery requires careful consideration of various factors, including durability, cost, and project requirements.

Data from the American Society for Metals indicates that about 70% of project failures are tied to poor material selection. It's essential to evaluate the specific properties of metals, such as strength, weight, and corrosion resistance. Each project has unique needs, making it crucial to align machine capabilities with those requirements.

However, many teams overlook the importance of thorough research. A rushed decision can lead to increased costs and wasted resources. Understanding how different machines process metals is also vital. The choice of metal and machine can lead to unforeseen challenges during production. Therefore, taking the time to analyze your options can prevent mistakes that might be avoidable.

Understanding the Different Types of Metals: Properties and Applications

When selecting metals for projects, understanding their properties is crucial. Different metals exhibit unique characteristics that influence their application. For instance, aluminum is lightweight and resistant to corrosion. It’s often used in aircraft and automotive components.

Copper, with its excellent conductivity, is ideal for electrical wiring.

Steel, a versatile choice, combines strength and durability. It is widely used in construction and machinery. However, one should consider the grade of steel. Higher grades are more resilient but can be more expensive. Choosing the wrong type can lead to failures.

Each metal has its drawbacks too. Stainless steel, while rust-resistant, can be hard to machine. This might increase production time and costs. It's essential to weigh these factors carefully. Think about the project's demands and budget. A poor metal choice can derail an entire project. Take the time to analyze your requirements deeply.

Evaluating Machine Options: CNC vs. Traditional Machining Techniques

When considering machine options for your project, CNC and traditional machining techniques each offer distinct advantages. CNC, or Computer Numerical Control, allows for precision and repeatability. It automates processes, reducing human error significantly. This can be crucial for complex parts that require tight tolerances. You can produce intricate shapes and details with remarkable accuracy. However, it often demands a larger upfront investment in machinery and training.

On the other hand, traditional machining techniques, like milling and turning, showcase their own set of benefits. These methods rely on human skill and experience. This can sometimes yield unique insights that automation cannot provide. Traditional machining can be more flexible for small batch sizes. Yet, there may be inconsistencies in quality, especially if multiple operators are involved. Crafting specific details can take longer.

In terms of material choice, different metals can impact your machining method. Lighter materials may work well with either technique, while tougher metals might necessitate CNC for effective handling. However, machines and metal selection often challenge project managers. Balancing cost and functionality is tricky. Each project might prompt you to revisit your choices and adapt.

2026 Metal and Machine Selection for Projects

Analyzing Project Requirements: Weight, Strength, and Durability Considerations

When embarking on a new project, understanding the weight, strength, and durability of materials is crucial. These factors directly affect the overall effectiveness and longevity of your work. For instance, if your project requires robust structural integrity, selecting a heavier metal might be essential. Consider steel or titanium. They excel in strength but can add significant weight.

Conversely, lightweight metals like aluminum can help maintain portability. This is particularly important for projects intended for mobility or frequent transport. Balancing weight against strength is often a challenge. It's easy to overlook how these elements impact each other. A lighter material may compromise durability over time, especially in harsh environments. Every project has its unique demands, which complicates the selection.

Lastly, consider the potential for corrosion or wear. Depending on the intended use, some metals may need additional treatments. Is it really worth the extra cost? Reflecting on such questions can guide you in making a more informed decision. Ultimately, your choices will be shaped by both practical needs and the vision for your project.

Cost-Benefit Analysis: Budgeting for Materials and Machinery in Projects

When embarking on a new project, budgeting effectively is crucial. The choice of metal and machinery can significantly influence costs. Metals like aluminum, steel, and copper each have different price points and properties. For instance, aluminum might be lighter and more resistant to corrosion. However, it can also be more expensive.

Machinery costs add another layer to the budget. Investing in quality equipment can reduce long-term expenses. However, startup costs can be daunting. You might find yourself overestimating what you need or underestimating maintenance costs. Always account for these potential pitfalls in your budget.

Cost-benefit analysis plays a vital role here. Consider not just the initial expenditure but also the long-term returns. Sometimes, cheaper materials may lead to increased expenses down the road. Finding the right balance between quality and cost requires careful consideration. Reflecting on past choices can help refine this process.

2026 How to Choose the Right Metal and Machine for Your Project? - Cost-Benefit Analysis: Budgeting for Materials and Machinery in Projects

| Material Type | Cost per Unit | Durability (Years) | Machine Required | Machine Cost | Total Cost |

|---|---|---|---|---|---|

| Aluminum | $2.00 | 20 | CNC Mill | $15,000 | $17,000 |

| Steel | $1.50 | 30 | Laser Cutter | $20,000 | $16,000 |

| Copper | $3.50 | 15 | Lathe Machine | $12,000 | $21,000 |

| Titanium | $6.00 | 40 | Milling Machine | $25,000 | $29,000 |

| Bronze | $4.00 | 25 | Cutting Machine | $18,000 | $26,000 |

Industry Trends: Innovations in Metalworking and Machine Technology for 2026

In 2026, the metalworking industry continues to evolve rapidly. Innovations in machine technology are reshaping how projects are executed. Automation is at the forefront. It brings efficiency but also challenges. Not every machine suits every task. Selecting the right equipment requires careful consideration.

New materials are gaining traction. Lightweight alloys and advanced composites are becoming popular. These materials may offer strength but can complicate machining processes. Operators must adapt their techniques. Training is essential, but finding the right resources can be difficult. Not every worker will embrace change easily, and this can stall progress.

Sustainability trends influence choices too. Eco-friendly machines are emerging. They reduce waste and energy consumption. However, initial costs may deter some businesses. Balancing budget constraints with innovation is crucial. Many companies struggle with this dilemma. These challenges present opportunities for growth and reflection.

Related Posts

-

What Is a Metal Works Machine? Types, Uses, and Key Features Explained

-

How to Choose the Best Machine Cutting Machine for Your Needs

-

Top 5 Best Shape Cutting Machines for Precision Cutting in 2023

-

How to Choose the Best Neatening Machine for Your Home or Office

-

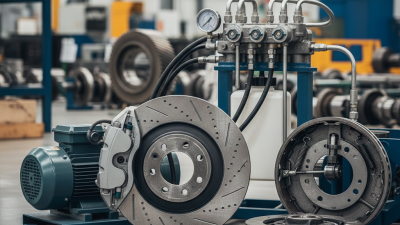

Top Brakes Machine Types for Efficient Performance in Various Industries?