10 Essential Tips for Choosing the Right Press Brake Machine

Choosing the right press brake machine is crucial for any metalworking shop. It can greatly impact production efficiency and product quality. However, this decision can be daunting due to various options available in the market. Each machine comes with unique features, specifications, and price points that can complicate the selection process.

When evaluating different press brake machines, consider specific factors. You might prioritize bending capacity, accuracy, and ease of use. The right machine can save time and reduce waste. Yet, it's easy to overlook essential aspects, leading to regrettable choices. Reflecting on your shop's needs is vital to avoiding mistakes.

In the end, picking the perfect press brake machine requires careful thought. Taking your time to weigh these tips can lead to better decision-making. Understanding both your immediate needs and long-term goals is key. This will ultimately enhance your workshop's performance and product output.

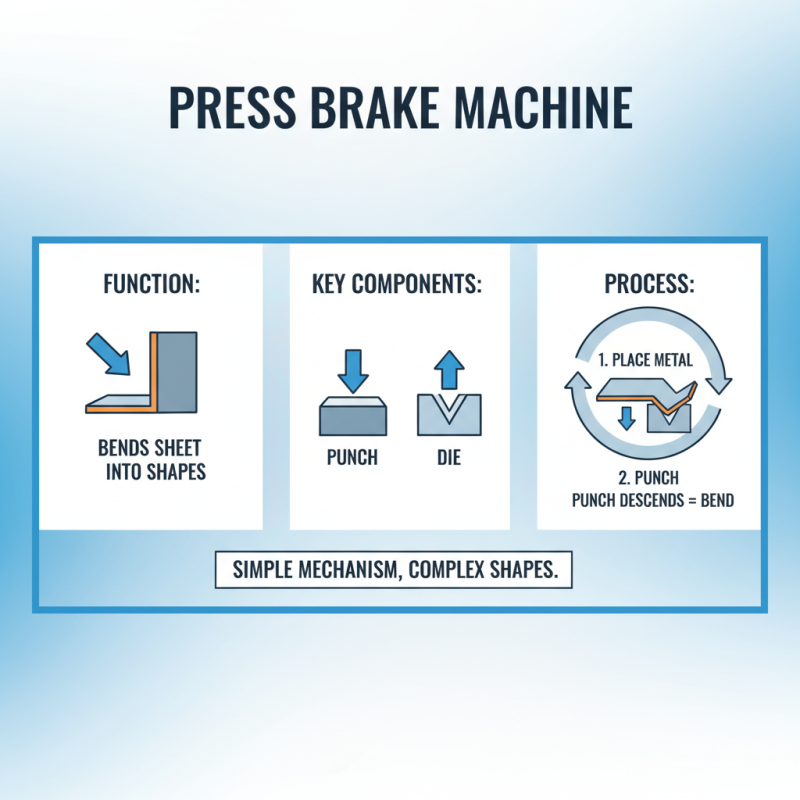

Understanding the Basics of Press Brake Machines

Understanding the basics of press brake machines is crucial for any metalworking operation. A press brake is designed to bend sheet metal into desired shapes. The process involves placing the metal between a punch and a die. When the punch descends, it creates the bend. This simple mechanism can produce complex forms.

However, choosing the right machine can be confusing. Many factors come into play, such as tonnage and bed length. Tonnage refers to the force the machine applies. It must match the thickness of the material. Bed length determines the maximum size of the material you can work with. Too small can limit your projects. Too large can lead to inefficiency.

Additionally, operators must consider control systems. Some machines use manual controls. Others employ advanced CNC technology. Understanding these options is essential. Mistakes can lead to waste and frustration. Reflecting on specific project needs can guide your choice. Think about the materials you’ll bend regularly. Analyze how often you’ll need to change settings. A thoughtful approach can streamline your workflow.

Key Features to Consider When Selecting a Press Brake

When selecting a press brake, it's crucial to consider the machine's bending capacity. This refers to the maximum force the machine can exert. Typically, this is expressed in tons. If your projects require extensive metal shaping, ensure the machine meets those demands. A lower capacity may lead to project delays or limit options.

Next, look at the working length of the machine. This determines the size of the materials you can process. A short machine may restrict your work to smaller sheets. Think about potential projects. Longer workpieces may require a machine with greater length or even multiple setups.

Another key feature is precision. Press brakes can vary in accuracy, impacting the quality of your final product. Machines with digital readouts or advanced control systems enhance this precision. Quality errors might crop up with lower-end models. It's essential to reflect on the potential trade-offs between cost and quality. You really want your investment to pay off in the long run.

10 Essential Tips for Choosing the Right Press Brake Machine

| Tip No. | Feature | Importance | Considerations |

|---|---|---|---|

| 1 | Machine Type | High | Choose between hydraulic, mechanical, or electric based on needs. |

| 2 | Bending Capacity | High | Ensure the machine can handle material thickness and width. |

| 3 | Back Gauge System | Medium | A reliable back gauge improves precision and efficiency. |

| 4 | Control System | High | Choose between manual controls, CNC, or programmable options. |

| 5 | Safety Features | High | Look for emergency stops, security guards, and sensors. |

| 6 | Material Compatibility | Medium | Ensure the press brake handles various materials you use. |

| 7 | Die and Punch Selection | Medium | Choose compatible dies and punches for your applications. |

| 8 | Machine Size and Weight | Low | Consider available shop space and machine mobility. |

| 9 | Power Requirements | Medium | Ensure compatibility with your shop's power supply. |

| 10 | Warranty and Support | High | Consider after-sales support and warranty terms. |

Evaluating Material Compatibility for Your Press Brake Needs

Choosing the right press brake machine involves understanding material compatibility. Different materials require different bending techniques and forces. For instance, aluminum is lighter and more pliable, while steel is tougher and needs more power. It’s crucial to assess the thickness and hardness of the material before selecting a machine.

Using the wrong machine can lead to inefficiencies. You might find that your press brake struggles with thicker materials. A press brake that’s not powerful enough will create poor bends. This could lead to wasted materials and increased costs. It’s also essential to consider the maximum capacity of your machine. Overloading it can lead to mechanical failures.

Reflect on your production needs. Are you working with a variety of materials? If so, a versatile press brake would be beneficial. However, if you mainly focus on one material type, a specialized machine might be the better option. Evaluating your specific requirements is key to making the right decision.

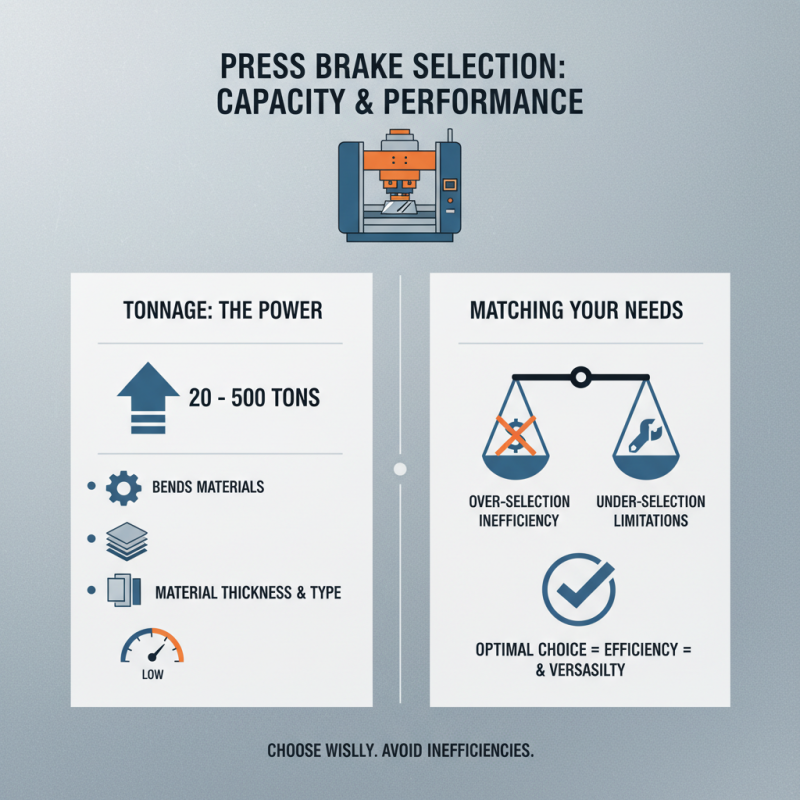

Assessing Machine Capacity and Performance Specifications

When choosing a press brake machine, assessing capacity and performance is crucial. Look at the machine’s tonnage. The tonnage determines your ability to bend different materials. A typical range is between 20 tons to 500 tons. Consider your needs to avoid over or under-selecting tonnage. Choosing the wrong capacity can lead to inefficiencies.

Performance specifications affect workflow. Pay attention to bending speed and accuracy. Reports show that machines with higher speeds can improve productivity by 20-30%. Accuracy is needed to maintain product quality. Even minor errors can lead to costly material waste. Evaluate the machine’s repeatability—ideal values often fall below 0.01 mm. Without this precision, businesses may face significant rework and delays.

Material compatibility is another key factor. Not every press brake works well with all materials. For example, stainless steel requires a different approach compared to aluminum. Understanding these nuances is essential. A mismatch can result in performance issues. Thus, reflect on your current and future needs before investing. Be mindful that cutting corners in capacity and performance can erode long-term success.

The Importance of Manufacturer Reputation and Support Services

When selecting a press brake machine, the manufacturer's reputation plays a crucial role. According to industry reports, about 30% of buyers prioritize a reliable manufacturer before making a decision. A trusted manufacturer ensures consistent quality and performance. This reputation often indicates the level of support and service provided post-purchase. A well-regarded brand typically offers accessible customer service. Quick responses can save time and boost productivity.

Support services greatly influence long-term satisfaction. Data shows that machines from high-reputation manufacturers have a 20% lower failure rate in their initial year compared to lesser-known brands. Downtime can be costly, leading to delayed projects and loss of revenue. Additionally, the right support services can help overcome technical challenges. Personalized training and accessible resources can enhance your team's expertise, minimizing potential mistakes.

Potential buyers should also consider user reviews. These can reveal valuable insights into service reliability. Stay aware that not all publishers of reviews are independent. Some may have biases, given their relationships with certain manufacturers. Gathering a range of opinions ensures a balanced understanding. The search for the right press brake is complex, requiring both diligence and reflection on your specific needs.

Comparison of Press Brake Machine Features

Related Posts

-

How to Choose the Best Arc Cutting Machine for Your Needs?

-

Top Brakes Machine Types for Efficient Performance in Various Industries?

-

Top 5 Best Shape Cutting Machines for Precision Cutting in 2023

-

How to Choose the Best Neatening Machine for Your Home or Office

-

10 Best Metal Fabrication Techniques You Should Know?

-

What Is a Metal Works Machine? Types, Uses, and Key Features Explained