Top Brakes Machine Types for Efficient Performance in Various Industries?

In the fast-evolving landscape of manufacturing, the type of brakes machine used can significantly impact operational efficiency. According to a report by Market Research Future, the global brakes machine market is expected to grow at a CAGR of 5.1% from 2021 to 2027. Different industries, such as automotive and aerospace, have unique requirements for braking systems, necessitating tailored solutions.

Many companies overlook the importance of selecting the right brakes machine. Choosing poorly can lead to inefficiencies, excessive downtime, and costly repairs. Data from the National Institute for Occupational Safety and Health indicates that even minor braking system failures can cause serious accidents, pointing to the necessity for reliable equipment.

The variety of brakes machines available can be overwhelming. Disc brakes, drum brakes, and hydraulic systems each serve different purposes. Understanding these options ensures better decision-making. As industries strive for enhanced performance, the right brakes machine becomes essential in maintaining safety and efficiency. A thoughtful approach to brake system selection is crucial for long-term success.

Types of Brake Machines: A Comprehensive Overview

When examining brake machine types, the variety is extensive. Each industry has unique demands. Hydraulic brake machines are prevalent in heavy manufacturing. They offer powerful clamping and precision. However, they can be complex to maintain. Operators need training to handle these machines safely.

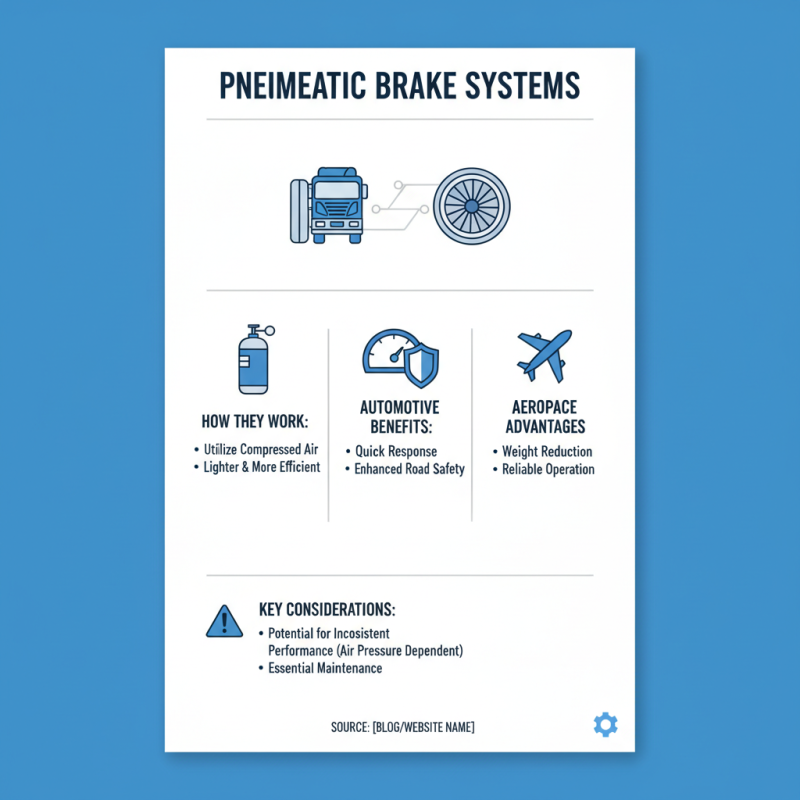

Pneumatic brake machines are commonly used in automotive sectors. They rely on air pressure, making them efficient. Yet, they require a consistent air supply. If the air pressure fluctuates, performance can decline. This aspect needs careful monitoring, as inconsistencies may lead to issues.

Electrical brake machines are gaining popularity due to their energy efficiency. They enable precise control over braking force. However, the initial investment can be high. Companies must weigh the cost against long-term savings. Maintaining these machines is also essential to prevent breakdowns. Overall, understanding the variety of brake machines is crucial for optimizing performance across industries.

Top Brakes Machine Types for Efficient Performance in Various Industries

| Brake Machine Type | Application Industry | Key Features | Maintenance Frequency |

|---|---|---|---|

| Hydraulic Brake Press | Manufacturing | High force, precise control | Monthly |

| Mechanical Shoe Brake | Automotive | Cost-efficient, easy to replace | Quarterly |

| Pneumatic Brake System | Transport | Instant response, efficient power use | Biannual |

| Electromagnetic Brake | Industrial Machinery | Quick activation, high reliability | Annually |

| Dynamic Brake | Energy Systems | Energy recovery, reduced wear | Seasonally |

Hydraulic Brake Machines: Applications and Advantages in Manufacturing

Hydraulic brake machines play a significant role in manufacturing. These machines provide exceptional control and precision. In industries like automotive and aerospace, the accuracy of hydraulic brakes ensures high-quality production. According to a recent report, about 50% of manufacturers noted improved operational efficiency when incorporating hydraulic systems.

One key advantage is their ability to handle complex tasks with ease. Hydraulic brake machines can exert substantial force while being compact. This is crucial in tight production spaces. Data shows that companies using hydraulic technologies report a 30% decrease in operational downtime. However, not all applications see equal benefits. Some users express concerns about maintenance costs and the need for skilled personnel.

In various sectors, it’s clear that hydraulic machines are vital. Yet, the initial setup can be challenging, particularly for smaller manufacturers. Adapting existing operations requires careful planning. Despite these hurdles, the potential for efficiency makes hydraulic systems appealing. Industries must weigh immediate challenges against future gains.

Pneumatic Brake Systems: Efficiency in Automotive and Aerospace Industries

Pneumatic brake systems play a crucial role in the automotive and aerospace industries. These systems utilize compressed air to operate, making them lighter and more efficient. In vehicles, they offer quick response times. This enhances safety on roads. However, the reliance on air pressure can sometimes lead to inconsistent performance. Maintenance becomes essential.

In aerospace, pneumatic brakes are vital for controlling landing gear. They ensure smooth and safe landings. But challenges exist. Changes in altitude can affect air pressure. This inconsistency may lead to performance issues. Engineers prioritize developing solutions to mitigate these risks. The pursuit of reliability remains a focus.

Moreover, training technicians to understand these systems is key. Improper handling can lead to failures. Regular checks and thorough knowledge are essential for optimal performance. These aspects highlight the importance of ongoing improvement in pneumatic brake technology. The balance between efficiency and safety is a continuous journey.

Electric Brake Machines: Innovations and Performance Metrics

Electric brake machines are transforming industries with their innovative designs. According to a recent industry report, the global electric brake market is projected to grow at a CAGR of over 6% through 2027. This growth highlights the increasing demand for efficient, reliable braking solutions across various sectors. The technology provides precise control, which enhances safety and performance in applications like automotive and aerospace.

Performance metrics are crucial for evaluating electric brake machines. Data indicates that these machines reduce stopping distances by as much as 30%. Such improvements can significantly impact operational efficiency. Industries are adopting these machines not only for their performance but also for energy savings. Many electric brake systems consume up to 20% less energy than traditional pneumatic systems. This efficiency can lead to lower operational costs, though the initial investment may be a concern for some companies.

While the benefits are clear, there are areas needing reflection. The high upfront costs may deter smaller businesses. Additionally, integrating advanced electric brake systems can require training. This potential barrier highlights the need for a balance between innovation and access. As industries embrace these technologies, continuous improvement and adaptation will be essential for maximizing their benefits.

Performance Comparison of Electric Brake Machines by Type

Comparative Analysis of Brake Machines in Industrial Efficiency Standards

Brake machines are vital in various industries. They ensure safety and efficiency in operations. The use of different types helps meet specific performance standards. Some machines excel in high-speed settings, while others perform better in durability tests.

When analyzing brake machines, look at key factors. Efficiency is often measured by stopping distance and response time. Some machines may struggle under heavy loads. Others may not be as quick to respond in emergency situations. These shortcomings need careful evaluation.

Environmental factors also play a role. Machines need regular maintenance to function at peak levels. Even the best machines can fail if not properly cared for. Each industry's demands can significantly influence which brake machine type works best. It’s essential to match the machine to operational needs for optimal performance.